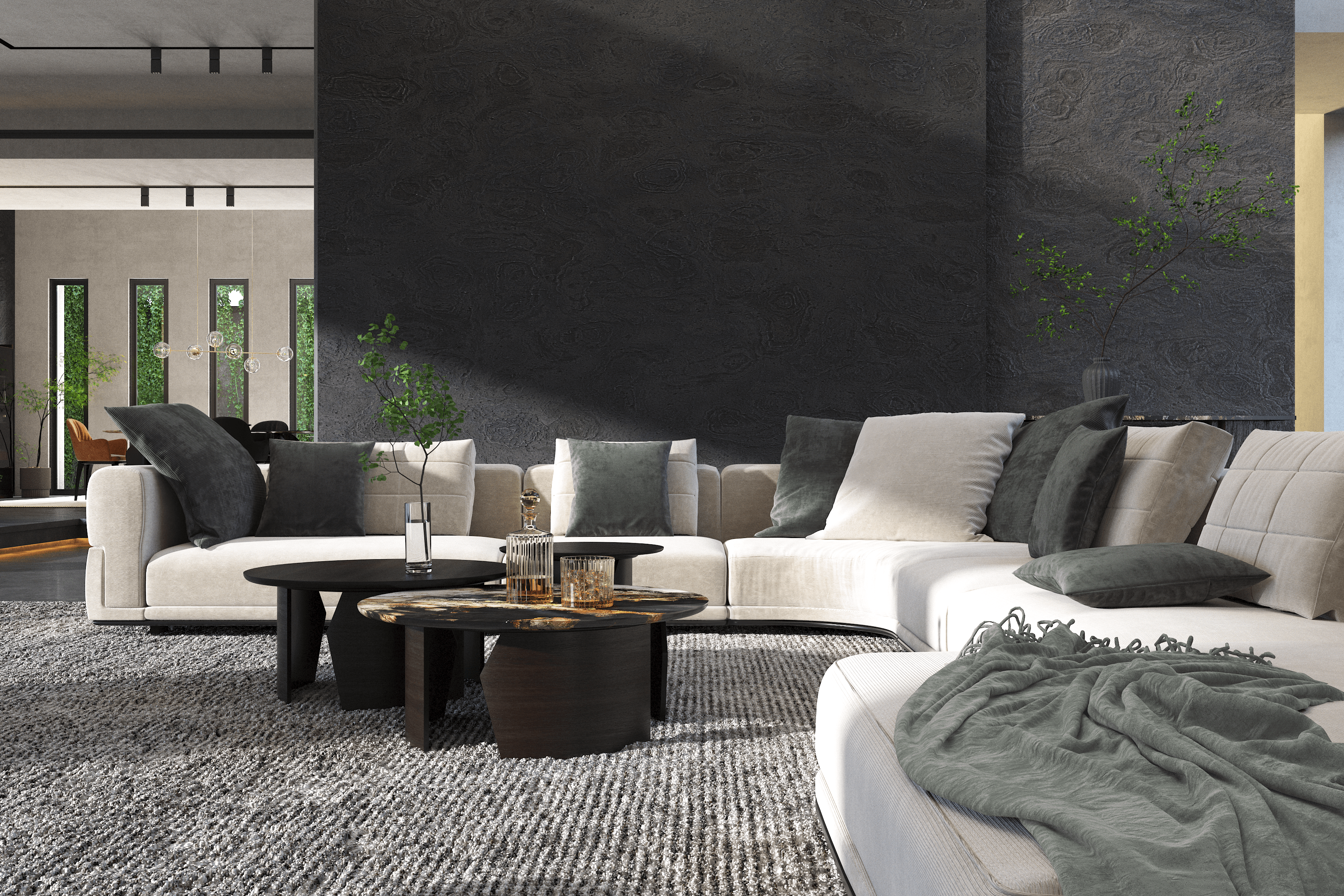

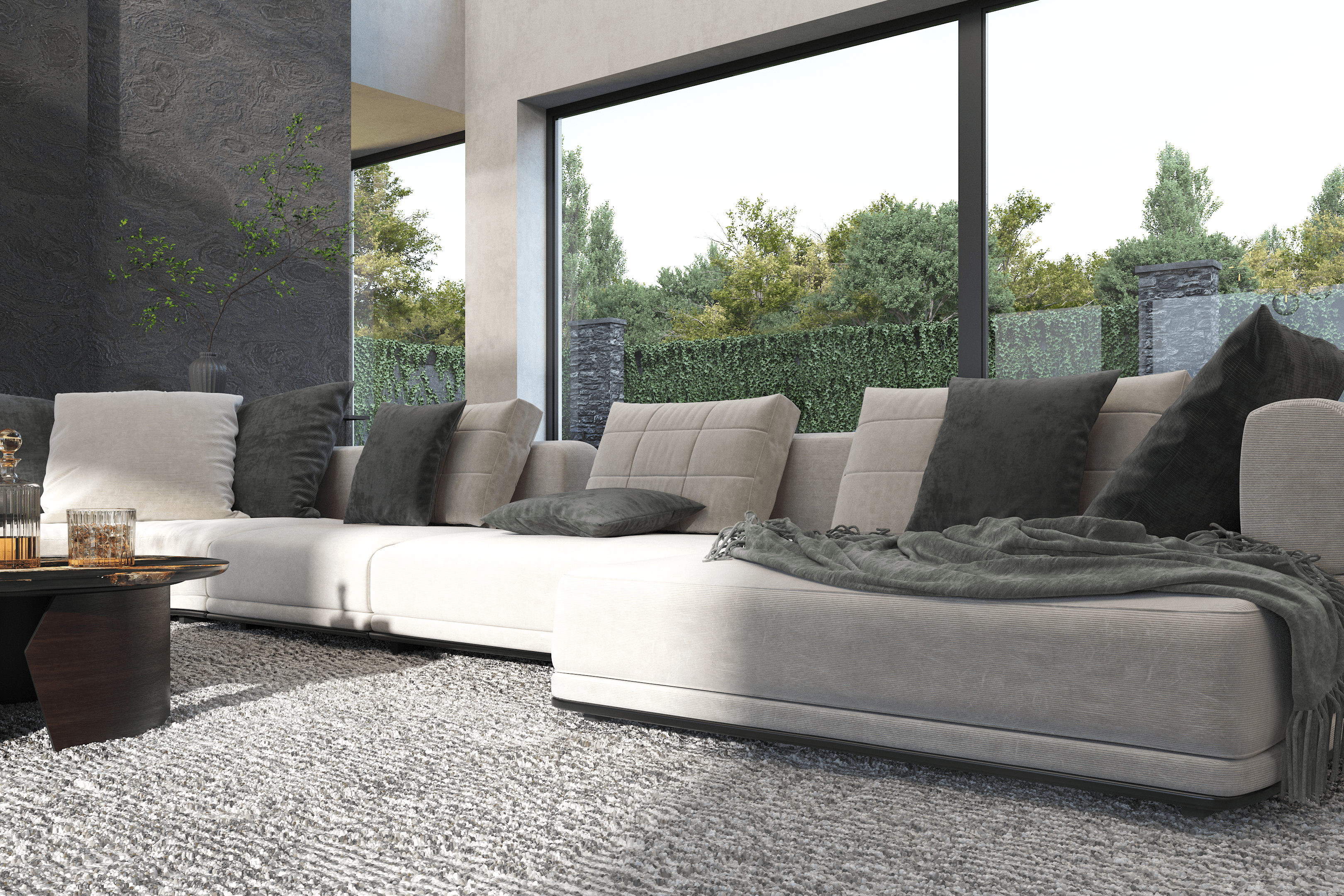

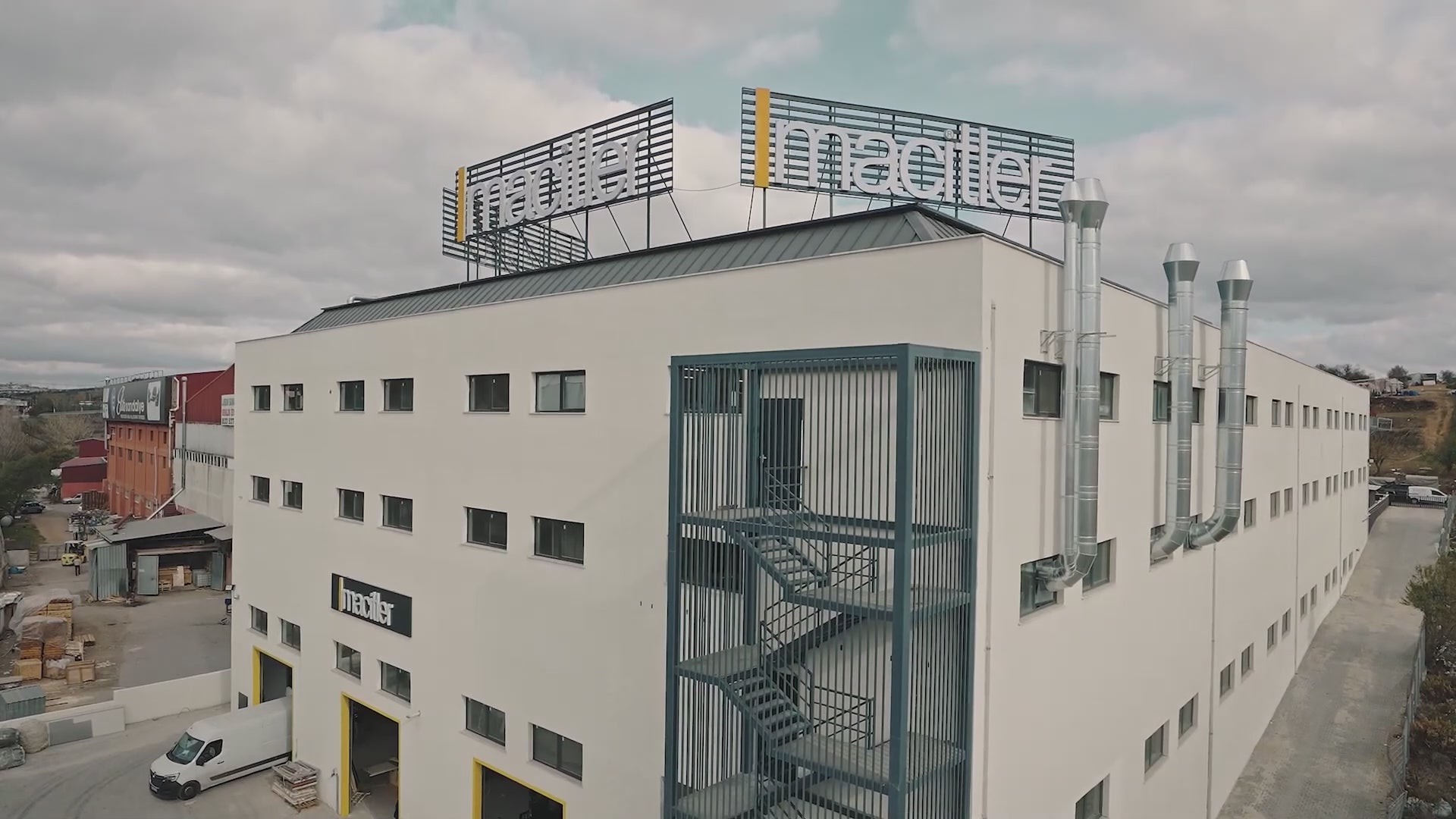

Quality-Focused Production

- All production processes are conducted in accordance with high-quality standards.

- Quality control is applied at every step from raw material selection to final assembly.

- Products are shipped after being evaluated in terms of sturdiness, durability, and aesthetics.

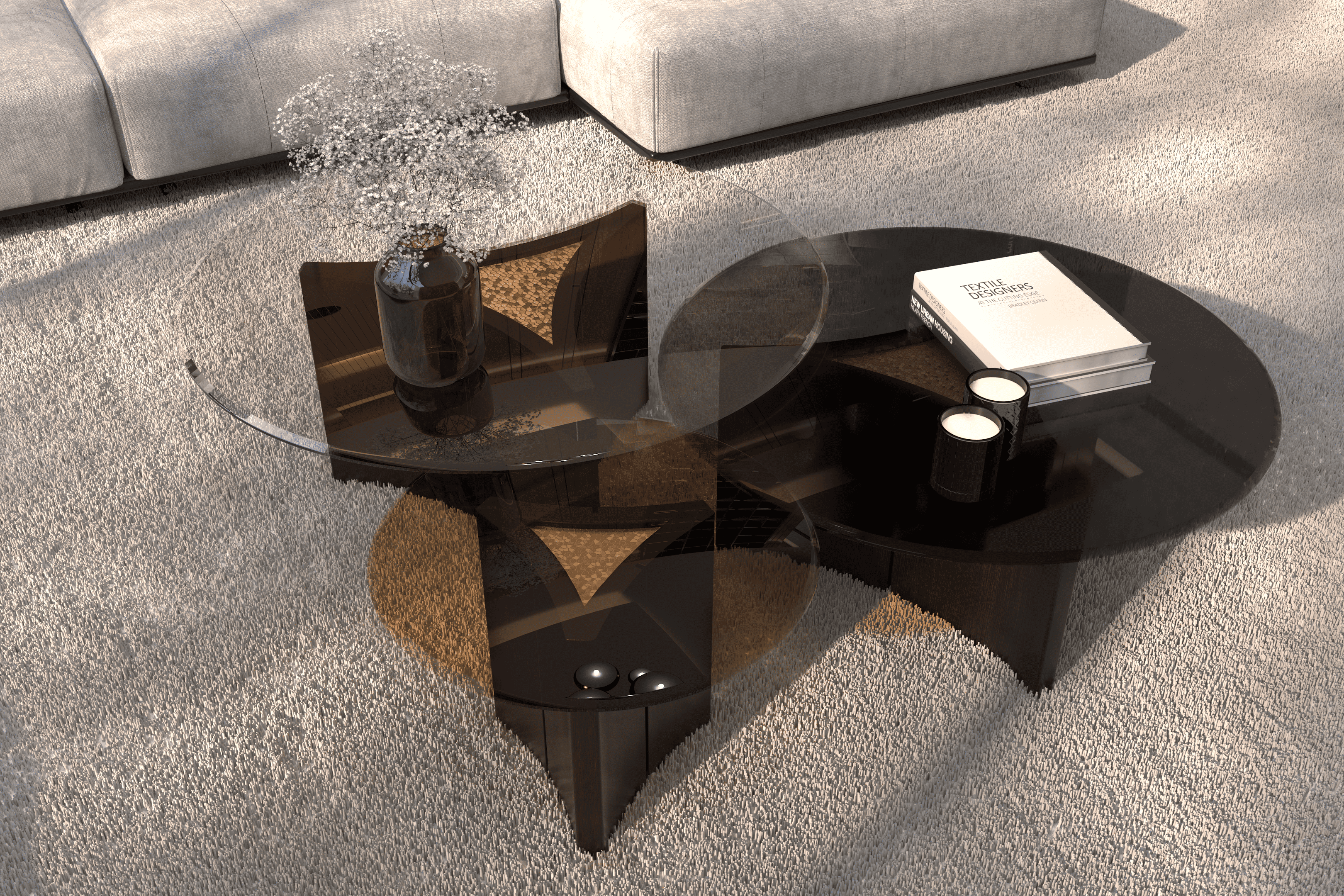

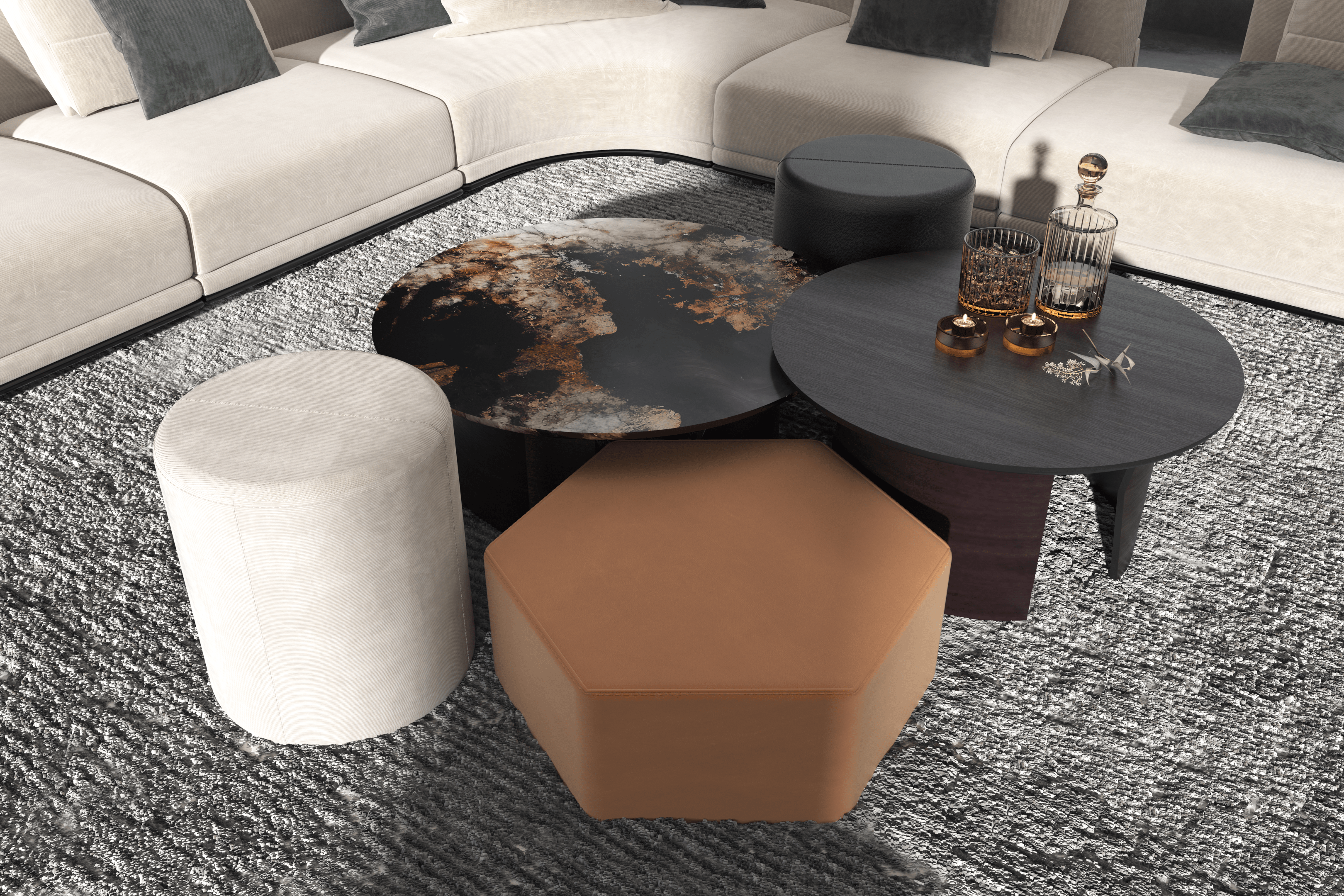

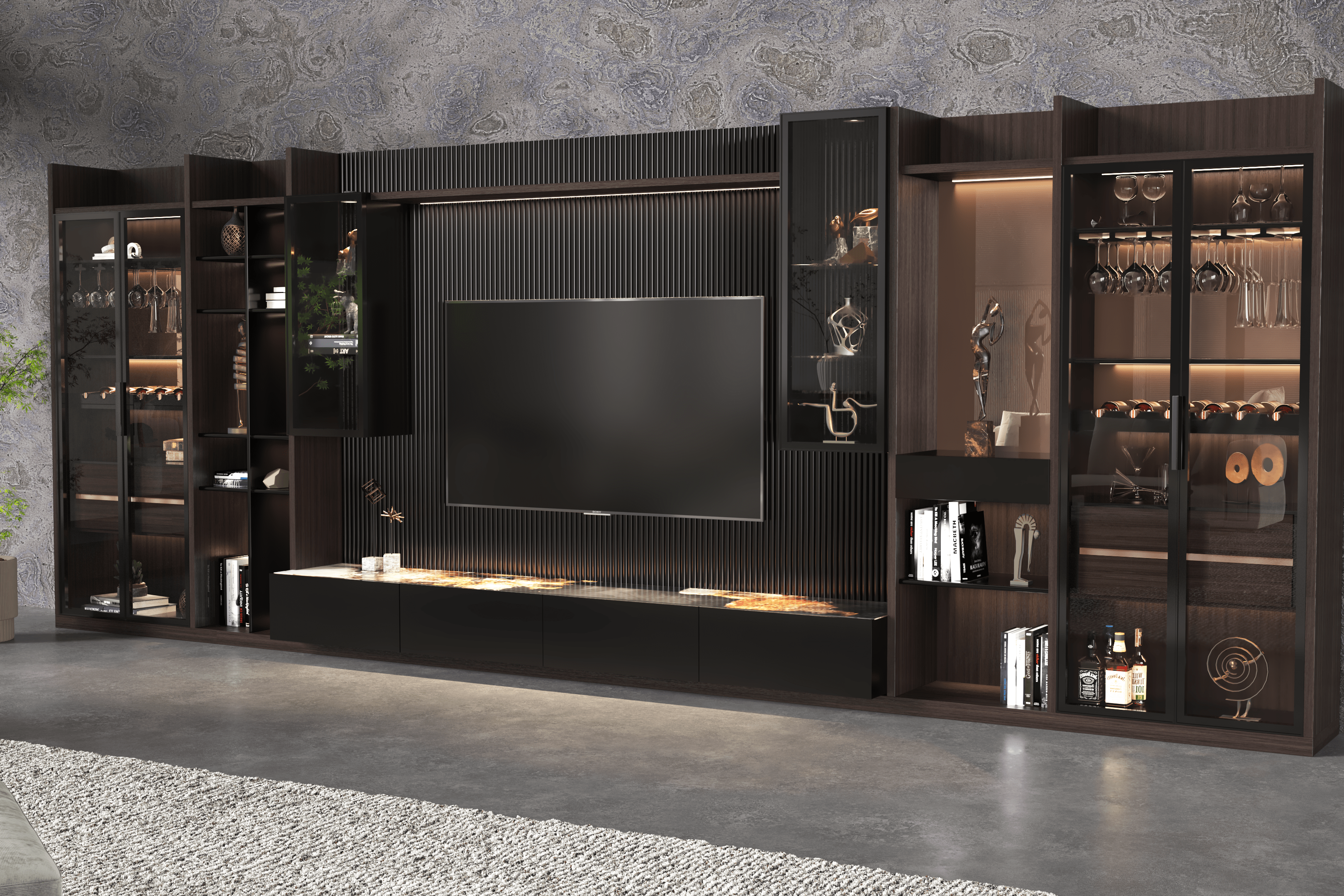

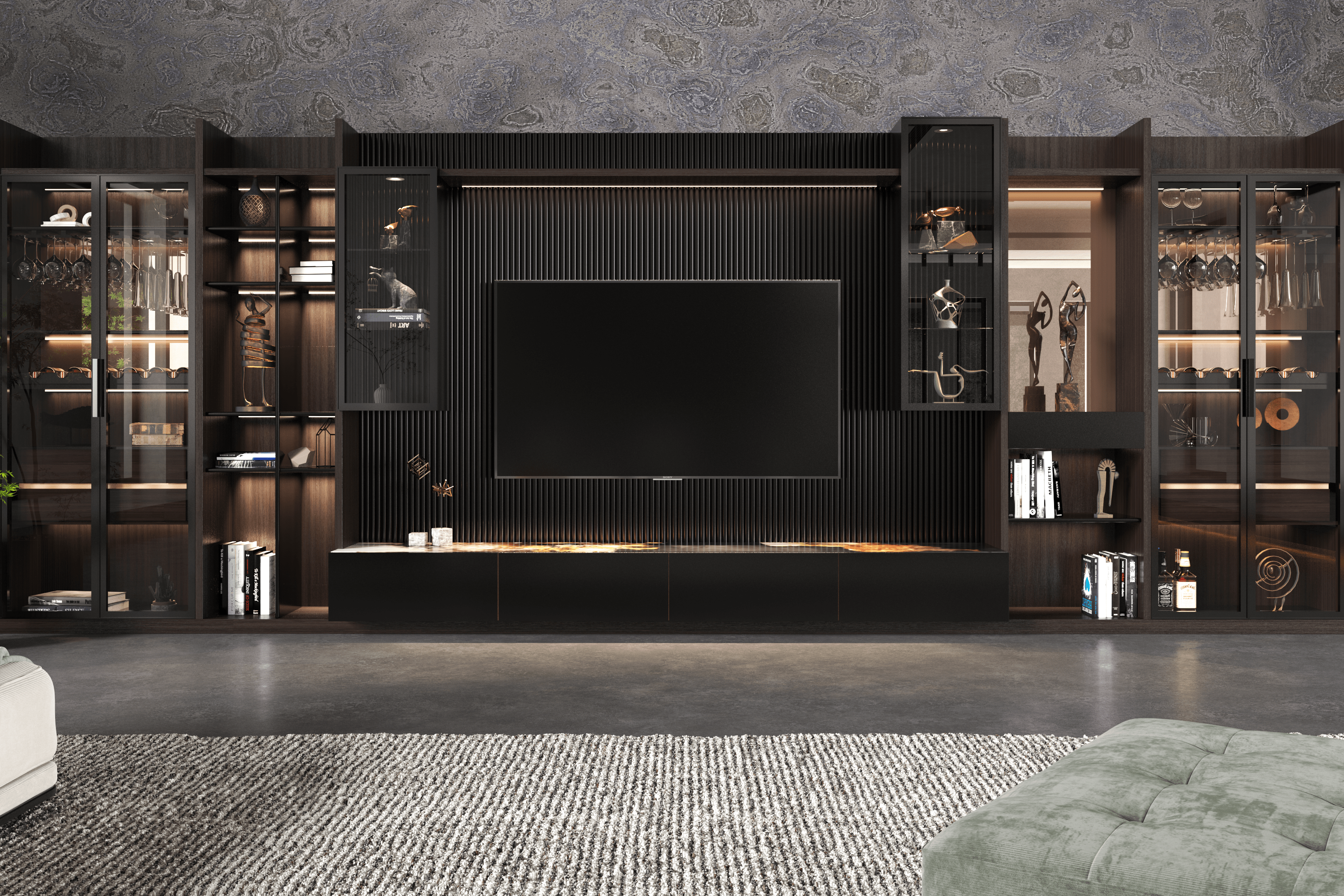

Customer-Focused Design & Production

- Customer needs, tastes, and usage habits are at the center of the production process.

- Custom requests for dimensions, colors, and fabrics are integrated.

- Pre-expectations are clarified with services like interior design and 3D modeling.